Composite Cure Visualization Program

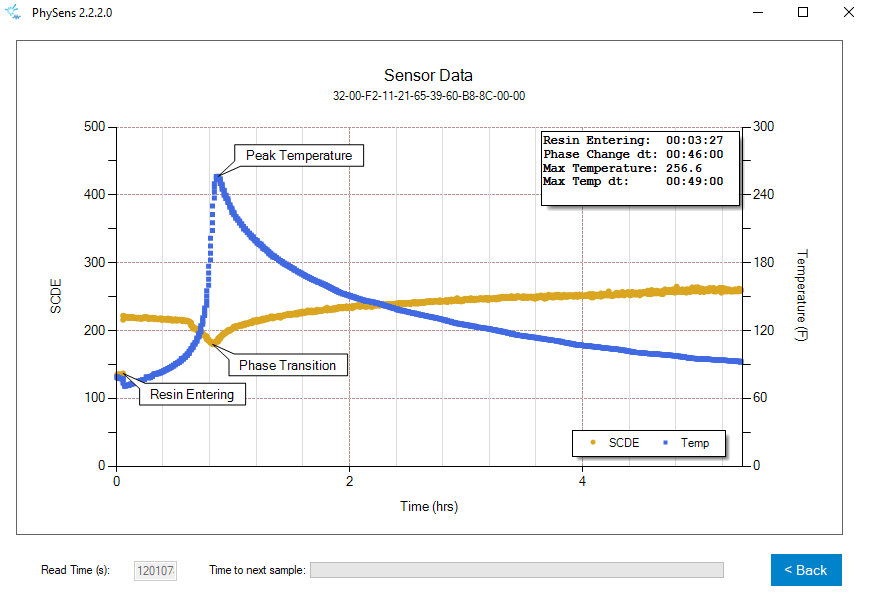

The Composite Cure Visualization Program is designed specifically to deliver a real-time cure state visibility prototype for Resin Transfer Molding (RTM), Compression RTM and most Resin Infusions applications (most aramids including carbon fiber):

- Accelerate composite customers' use of wireless, battery-free sensors

- Monitoring prepreg Out Life and provide real-time visibility into the cure state of Resin Transfer Molding (RTM), Compression RTM and most Resin Infusions

- Delivers working prototype for management approval built on years or SensThys experience of this nuanced technology

To learn more about the "CompCure" program:

What is included in the program?

- 2-days on premise site-survey (US only) & proof-of-concept set-up

- All system components: Hardware, sensors, software and services

- Material analysis

- Equipment set-up, calibration and guaranteed up-time

- Sensor characterization and selection

- Delivers working prototype for management approval

- Bootstrap customer from zero to hero

What happens at the end?

Program ensures the exploration of wireless, battery-free sensors is positive, rapid and results in a management approval ready prototype unique to your composite use-case.

- Onsite work guarantees successful proof-of-concept

- Team develops a full roll-out plan to duplicate success to other lines/facilities

The program includes:

- Wireless/battery-free sensors

- Dielectric/temperature/strain

- Sensor Interrogation hardware

- Simple sensor monitoring software

- 2-day on-site prototype preparation (US only)

- 6-months guaranteed hardware availability “Hot swap” minimizes down-time

Ready to find out more?

Learn about working with us to get your manufacturing line leak-detection operational!